Metal Electroplating Services

High-Performance Nickel–Chrome Electroplating for Metal Components

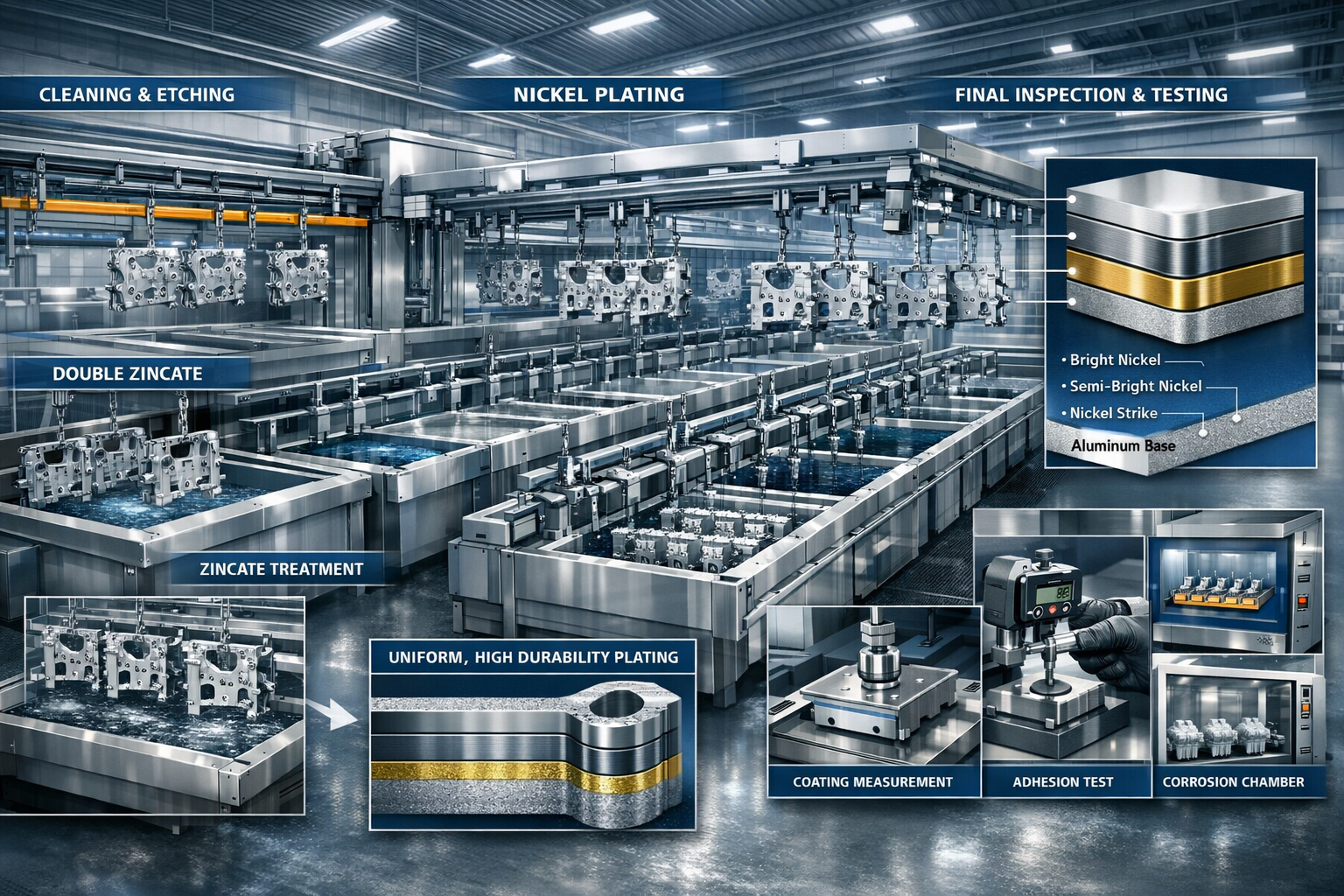

We provide advanced metal electroplating services designed to deliver superior corrosion resistance, durability, and premium surface finish. Our core expertise lies in nickel–chrome plating, with special focus on duplex and 3-step nickel systems, widely used in automotive, appliance, sanitary, electrical, and industrial applications.

By combining controlled process parameters, modern plating lines, and in-house laboratory testing, we ensure consistent quality across high-volume and precision metal components.